Could including a biostimulant seed treatment when sowing cover crops be the key to better establishment and increased soil health gains? CPM accesses the latest trial results to find out more.

By Janine Adamson and Rob Jones

“Regardless of the type of cover crop, establishment is key, there’s not much point doing it if it doesn’t achieve its purpose or true potential.”

Biostimulants and cover crops – the benefits of the two in isolation are widely publicised and as a result, their use is now commonplace across many UK farms. But what happens when they’re combined together? Furthermore, could this approach help growers in the North to improve cover crop establishment?

Pondering this concept led to ProCam running an experiment at their trial site at Stockbridge Technology Centre at Cawood in North Yorkshire, working with a seed treatment biostimulant from Unium Bioscience.

However, an initial hurdle had to be overcome – understanding how to apply a biostimulant to the cover crop seed in the first place. “We’ve traditionally worked with liquid-based seed treatment biostimulants which although very positive, do have some logistical limitations,” says Unium’s Andrew Cromie.

“They’re mostly designed to go through conventional seed treatment systems such as those which dress cereal seed. But some crops such as maize arrive pre-bagged, or in the case of grass, treated seed can clump which is problematic later on,” he explains.

Taking inspiration from the USA and its use of graphite, Unium realised there was greater potential to use the technology for UK-based applications.

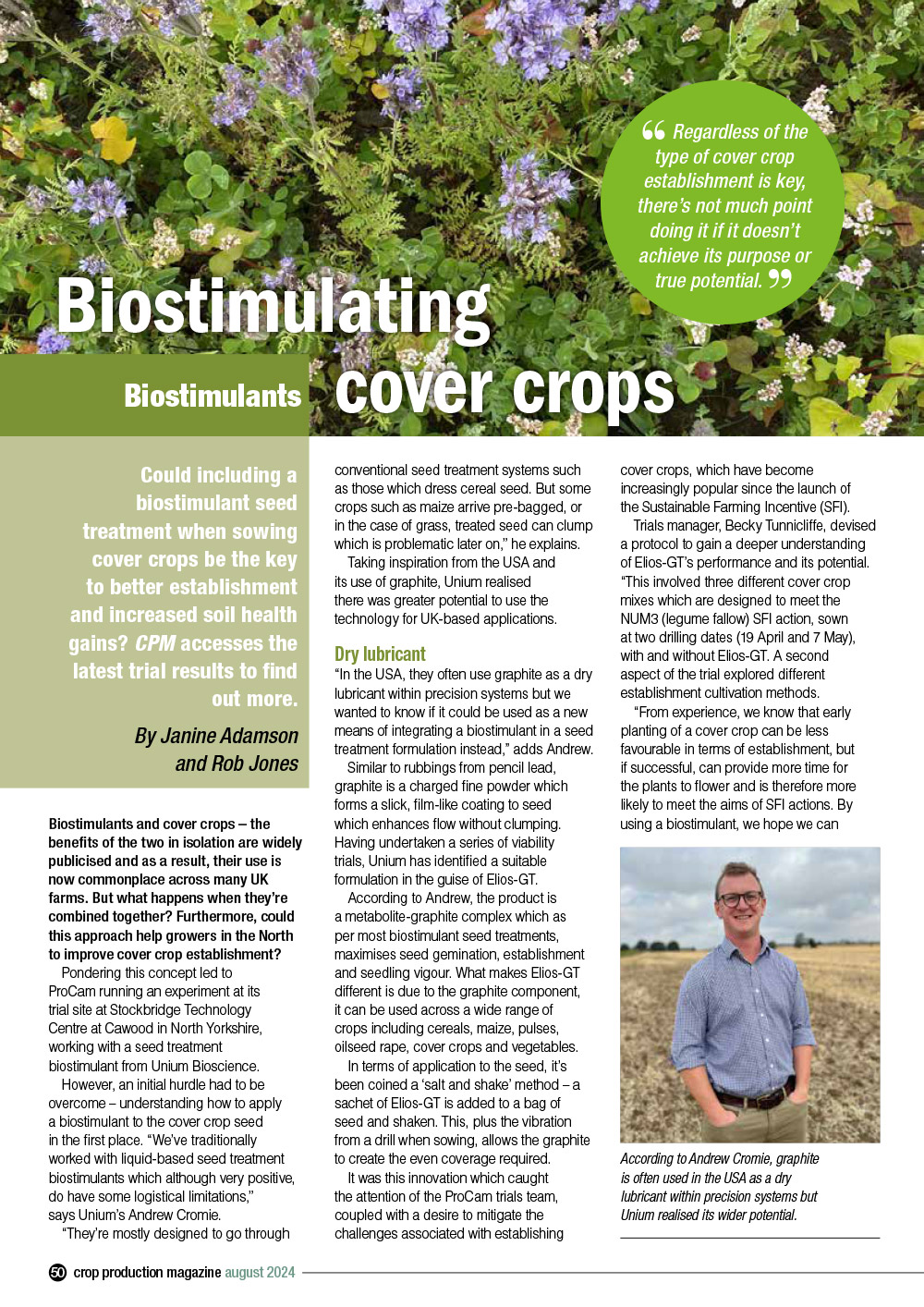

“In the USA, they often use graphite as a dry lubricant within precision systems but we wanted to know if it could be used as a new means of integrating a biostimulant in a seed treatment formulation instead,” adds Andrew.

Similar to rubbings from pencil lead, graphite is a charged fine powder which forms a slick, film-like coating to seed which enhances flow without clumping. Having undertaken a series of viability trials, Unium has identified a suitable formulation in the guise of Elios-GT.

According to Andrew, the product is a metabolite-graphite complex which as per most biostimulant seed treatments, maximises seed gemination, establishment and seedling vigour. What makes Elios-GT different is due to the graphite component, it can be used across a wide range of crops including cereals, maize, pulses, oilseed rape, cover crops and vegetables.

In terms of application to the seed, it’s been coined a ‘salt and shake’ method – a sachet of Elios-GT is added to a bag of seed and shaken. This, plus the vibration from a drill when sowing, allows the negatively charged graphite to create the even coverage required.

It was this innovation which caught the attention of the ProCam trials team, coupled with a desire to mitigate the challenges associated with establishing cover crops, which have become increasingly popular since the launch of the Sustainable Farming Incentive (SFI).

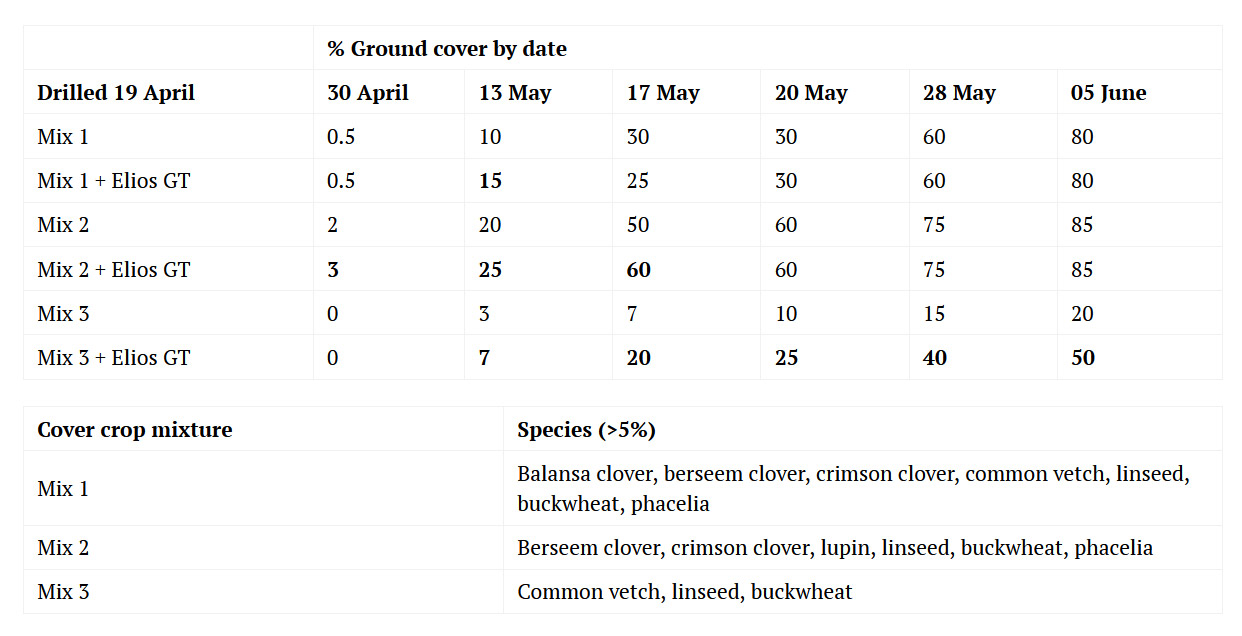

Trials manager, Becky Tunnicliffe, devised a protocol to gain a deeper understanding of Elios-GT’s performance and its potential. “This involved three different cover crop mixes which are designed to meet the NUM3 (legume fallow) SFI action, sown at two drilling dates (19 April and 7 May), with and without Elios-GT. A second aspect of the trial explored different establishment cultivation methods.

“From experience, we know that early planting of a cover crop can be less favourable in terms of establishment, but if successful, can provide more time for the plants to flower and is therefore more likely to meet the aims of SFI actions. By using a biostimulant, we hope we can overcome this challenge and improve biomass and ground cover,” she says.

With this year’s unfavourable spring conditions, Becky points out that 19 April was the earliest possible opportunity to drill the plots and where possible, planting would have taken place earlier. Equally, with cold, wet weather continuing throughout spring, the 7 May plots were only sown once soils were warm and moist, however struggled to flower until much later than anticipated.

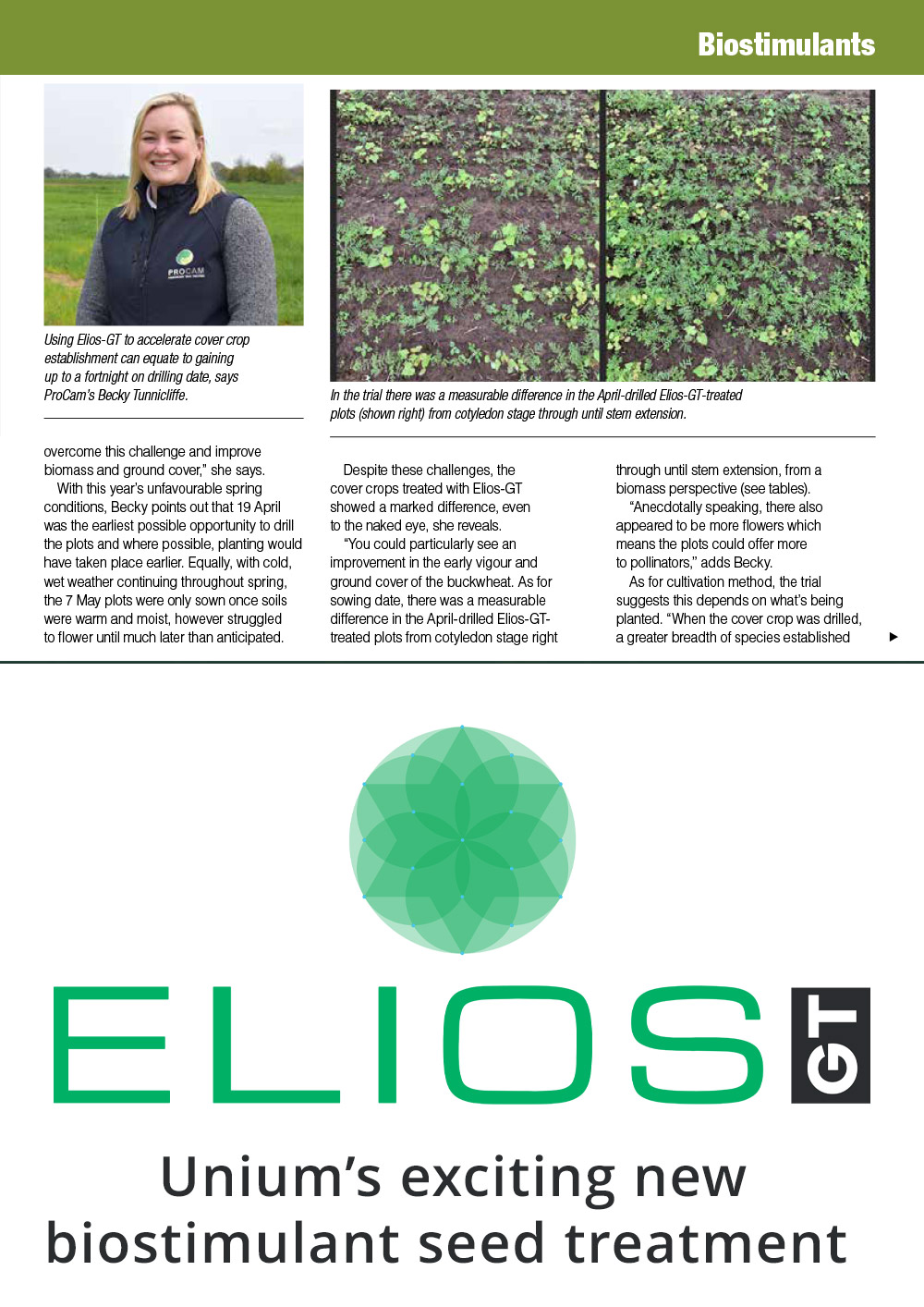

Despite these challenges, the cover crops treated with Elios-GT showed a marked difference, even to the naked eye, she reveals.

“You could particularly see an improvement in the early vigour and ground cover of the buckwheat. As for sowing date, there was a measurable difference in the April-drilled Elios-GT-treated plots from cotyledon stage right through until stem extension, from a biomass perspective (see tables).

“Anecdotally speaking, there also appeared to be more flowers which means the plots could offer more to pollinators,” adds Becky.

As for cultivation method, the trial suggests this depends on what’s being planted. “When the cover crop was drilled, a greater breadth of species established successfully compared with when the seed was broadcast due to improved seed-to-soil contact. In fact, the buckwheat pretty much failed in this instance.

“We’ve also seen variation in the success rates of the different mixes as a whole – mixtures with more species diversity have established better, achieving good levels of biomass by June. Whereas a less diverse mix with a high proportion of buckwheat and vetch, haven’t done so well,” she says.

So what does Becky believe this means? “Using Elios-GT to accelerate establishment can equate to gaining up to a fortnight on drilling date, which is particularly helpful in the North where soils take longer to warm up. This year at Stockbridge was the perfect demonstration of that – really tough conditions and cold, wet soils – so Elios-GT impressed even more.

“With longer in the ground, the cover crops then have a greater chance of delivering the environmental gains and meeting the aims of the appropriate SFI action. With these NUM3 mixes this meant the provision of food for pollinators, improving soil health and suppressing grassweeds,” she suggests.

“Beyond that, the trial indicates the importance of treating a cover crop with the same attention to detail as a conventional break crop, not cutting corners with establishment method, and using other tools to ensure good survival and rapid growth when conditions are sub-optimal.”

North Yorkshire agronomist Josh Baker believes as well as meeting SFI criteria, biostimulating cover crops has the potential to deliver much more. “With improved biomass comes better soil cover which means less erosion and increased organic matter – just some of the original aims behind using cover crops in the first place.

“There’s also the concept of weed suppression – part of the guidance for several SFI actions including NUM3 legume fallow and AHL1 pollen and nectar mix, is that herbicides can’t be used once the cover crop is established meaning a full canopy is the only way to manage the weed seed-bank,” he points out.

“With changes for NUM3 going into 2024 meaning this action is no longer rotational, considering weed burden and the risk associated with poor suppression is critical. Reducing cover crop seed rates or opting for more cost-effective mix options might reduce initial seed costs, but could incur greater spend with herbicides later in the rotation.”

Furthermore, he says early emergence is a critical stage for weed suppression and if this isn’t managed correctly, it can be difficult for a cover crop to overcome the subsequent competition. “Therefore it’s encouraging to see how Elios-GT boosts emergence, particularly in the challenging conditions we experience in the North,” adds Josh.

“Having now seen the trials, it’s definitely something I’m keen to try in the field. Regardless of the type of cover crop, establishment is key, there’s not much point doing it if it doesn’t achieve its purpose or true potential.”

A final benefit Josh highlights is the fact Elios-GT is a separate seed treatment which the grower can apply themselves, without a tie to specific mixes. “Equally, undertaking a separate pass through a cover crop, such as to apply a liquid biostimulant or fertiliser, is both dependent on field conditions as well as weighing up the associated machinery costs.

“Being the graphite formulation makes for a convenient and appealing delivery mechanism,” he concludes.

This article was taken from the latest issue of CPM. Read the article in full here.